Development of a fail-safe braking device for seismic isolation using low yield point steel: Safeguarding seismic isolated buildings from unexpectedly large earthquakes

Kawakin Core-Tech Co., Ltd. (Head office: Kawaguchi - Saitama; President: Suzuki Shinyoshi), in collaboration with Hazama Ando Co., Ltd. (Head office: Minato - Tokyo; CEO: Kuniya Kazuhiko) and Heiwa Hatsujo Co., Ltd. (Head office: Osaka; CEO: Haruki Hiroyuki), has developed a fail-safe braking device to further ensure the safety of buildings with seismic isolation structures in the event of a major earthquake such as a Nankai Trough earthquake.

Photo 1: Fail-safe braking system performance demonstration experiment

1. Development Background

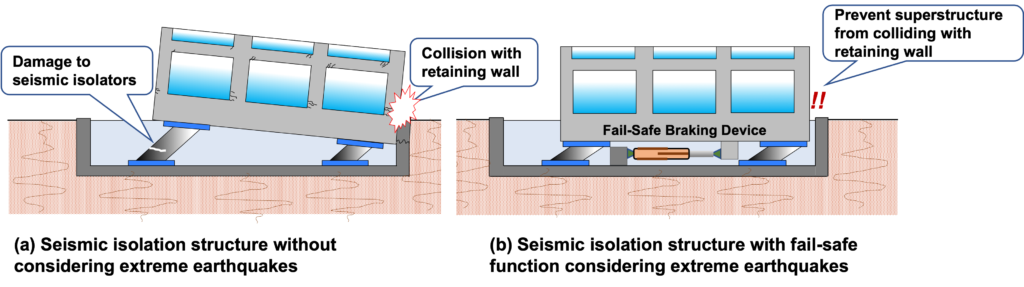

When a huge earthquake such as the Nankai Trough earthquake occurs, it is expected that the seismic isolation bearings and dampers of seismically isolated buildings will repeatedly undergo large deformation due to the long-lasting long-period seismic motion. As a result, the energy absorption performance of these will decrease, and the deformation of the seismic isolation bearings will exceed the range assumed in the design, increasing the risk of the superstructure colliding with the retaining wall surrounding the seismic isolation layer.

Since April 2017, new seismically isolated buildings constructed in the Kanto, Shizuoka, Chukyo and Osaka regions are required to be verified for safety in consideration of the impact of a massive earthquake that is expected to occur along the Nankai Trough, in accordance with technical advice from the Ministry of Land, Infrastructure, Transport and Tourism (Note 1).

The following methods are considered as technologies to deal with large earthquakes.

⚫︎ Increase the distance (seismic isolation clearance) between the retaining wall and the superstructure

⚫︎ Install many dampers to suppress horizontal displacement of the superstructure

The former leads to increased construction costs and reduced building volume, while the latter increases the response acceleration of the superstructure, resulting in reduced seismic isolation performance in earthquakes (design range) that should be taken into consideration under the Building Standards Act. To solve these problems, we are working on the development of a fail-safe braking device (Figure 1).

Figure 1: Seismic isolation structure without considering extreme earthquakes and

Seismic isolation fail-safe structure

2. Overview of the fail-safe braking device

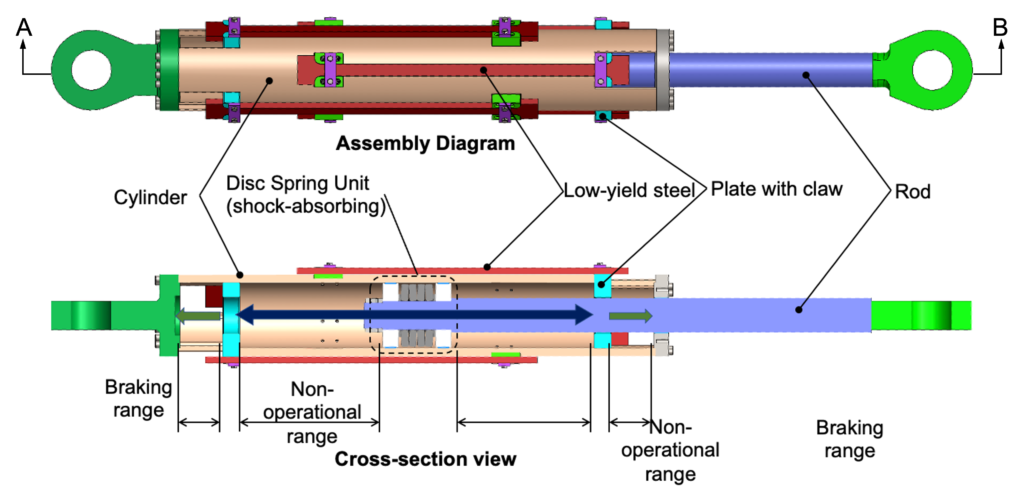

The fail-safe braking device (Figure 2) is an innovative device that prevents excessive horizontal displacement of the superstructure (braking) when a major earthquake that exceeds the design range occurs. It has the following features.

・Extreme earthquake countermeasures are possible without expanding the seismic isolation clearance.

・It does not affect the seismic isolation performance of the seismic motion considered in the design.

・The braking force uses the force caused by the plastic deformation (Note 2) of low-yield-point steel, and has a high energy absorption capacity. This minimizes damage to the superstructure.

・Because of a simple structure, it can withstand long-term use.

・The shape of the mounting part is the same as that of the seismic isolation oil damper, making it easy to install.

Figure 2: Overview of the fail-safe braking system

3.Demonstration of performance during a huge earthquake using the full-scale seismic isolation testing machine E-Isolation

In February 2024, we conducted a performance demonstration experiment of the fail-safe damping device using the full-scale seismic isolation testing machine E-Isolation owned by the Seismic Isolation Research Promotion Organization (Photo 1). E-Isolation will begin operation in June 2023 as the first facility in Japan capable of testing seismic isolation bearings and damping dampers at loads and speeds acting in actual earthquakes. As a civilian development and utilization initiative, this is the first of its kind.

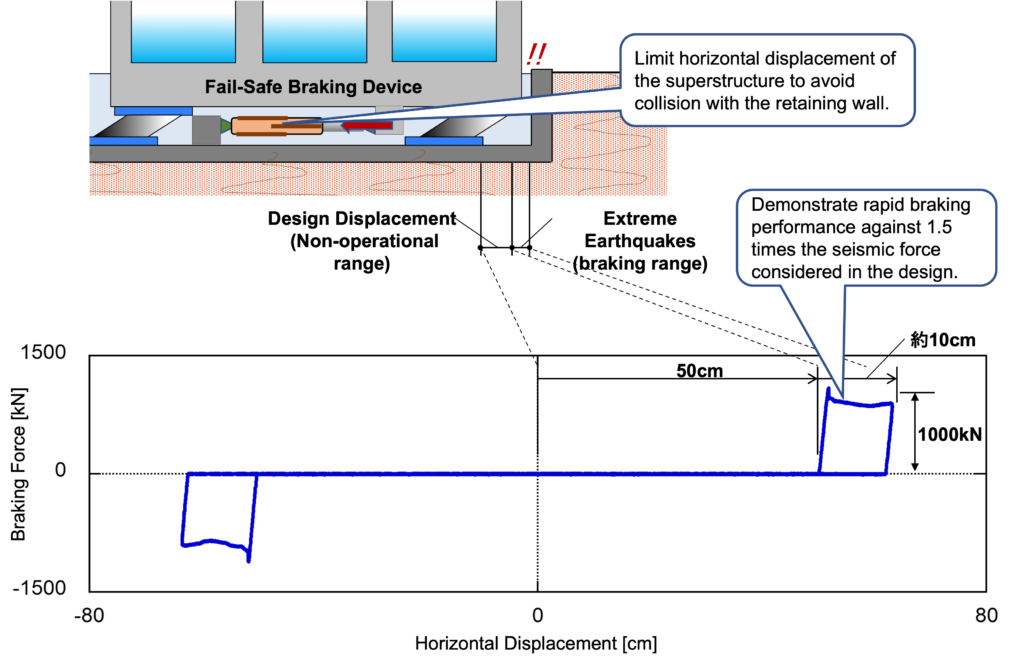

Through demonstration experiments, it was confirmed that, for the assumed seismic isolation clearance of 60 cm for the seismic isolated building, no damping force is generated at horizontal displacements of ±50 cm within the design range (insensitive zone), and that this does not affect the seismic isolation performance of the superstructure. On the other hand, in the event of a major earthquake, it was demonstrated that the superstructure can avoid colliding with the retaining wall within a damping zone of approximately 10 cm, and that at that time, damping is performed quickly with a damping force of approximately 1000 kN, which has a high energy absorption capacity (Figure 3).

In the future, we plan to widely apply this device to both new and existing seismic isolated buildings, working to improve the safety and security of seismic isolated buildings in the event of a major earthquake.

Figure 3: Restoring force characteristics of a fail-safe braking device

(Note 1) Technical advice from the Ministry of Land, Infrastructure, Transport and Tourism

National Housing Guidance No. 1111 (June 24th, 2016)

"Measures for long-period earthquakes in super-high rise buildings due to massive earthquakes along the Nankai Trough"

(Note 2) Plastic deformation of low yield point steel

Plastic deformation is when steel is deformed by applying force and does not return to its original length even when the force is removed. Low yield point steel is a material with particularly excellent plastic deformation performance.

<Contact>

Kawakin Core-Tech Co., Ltd. Construction Sales Department

2-2-7 Kawaguchi, Kawaguchi City, Saitama, 332-0015

TEL: 048-259-1161 FAX: 048-259-1137

Mail: info@kawakinkk.co.jp

INQUIRY FORM